When you hear "nuclear power," what comes to mind? For many, it's the incredible energy potential, but for some, it's a flicker of concern about safety. The truth is, the very heart of nuclear power – harnessing the atom's immense energy – is intrinsically linked to an equally immense commitment to safety. This commitment manifests in an intricate web of Control and Safety Systems in Nuclear Power Plants designed to monitor, regulate, and protect every facet of operations, ensuring that the power plant remains a fortress of stability.

These systems aren't just an afterthought; they're the vigilant guardians, constantly watching over the reactor, ready to act with precision and speed far beyond human capability. They are why, despite the inherent power within, nuclear plants are among the safest and most rigorously regulated industrial facilities on Earth.

At a Glance: Nuclear Plant Safety Systems

- Always Watching: Control systems continuously monitor temperature, pressure, neutron flux, and radiation levels.

- Digital Precision: Modern digital systems offer unparalleled accuracy, speed, and reliability.

- Layers of Defense: From automatic shutdowns to physical containment structures, safety is built in layers.

- Human Expertise: Operators are trained extensively to understand, interact with, and respond to these complex systems.

- Redundancy is Key: Critical functions have multiple backups, ensuring no single failure compromises safety.

- Evolving Protection: Systems are regularly upgraded, regulated, and tested against new threats, including cyberattacks.

The Unseen Guardians: What Are Control Systems?

Imagine a symphony orchestra where every instrument plays perfectly in tune and time, without a conductor physically present at every moment, because they've all been pre-programmed with precise instructions and self-adjusting mechanisms. That's a bit like how control systems operate in a nuclear power plant. They are the brains behind the brawn, integrating various components to manage nuclear fission, optimize efficiency, and, most critically, prevent hazards.

They achieve this by monitoring a myriad of parameters—everything from the core's temperature and pressure to the exact neutron flux—and making instantaneous adjustments. Without these systems, safely harnessing nuclear energy would be impossible.

Traditionally, nuclear plants relied on analog systems, which process continuous electrical signals. While robust for their time, they had limitations in precision and flexibility. Today, the industry has largely shifted to digital control systems. These offer significant advantages: enhanced precision, superior reliability, faster data processing, and built-in redundancy and fault tolerance that analog systems simply couldn't match.

The Specialized Tools in the Control Arsenal

Within the broad category of control systems, several specialized types work in concert to manage the plant's vast operations:

- Distributed Control Systems (DCS): Think of a DCS as the plant's central nervous system. It facilitates centralized management by distributing control functions across multiple locations. From a single control room, operators can monitor critical parameters like reactor temperature and pressure in real-time, making informed decisions that enhance both safety and operational efficiency. The ability to manage complex processes from one hub while executing commands locally is a game-changer.

- Programmable Logic Controllers (PLC): PLCs are the workhorses for specific, often repetitive, electromechanical tasks. Need a valve to open automatically when pressure exceeds a certain limit? Or a pump to stop if a tank is full? That's a PLC at work. They execute predefined safety protocols in demanding, industrial environments, acting as the silent enforcers of operational limits.

- Advanced Digital Control Systems: This represents the cutting edge. These systems integrate modern computing, sophisticated algorithms, and advanced data analytics. They go beyond mere monitoring and control, actively optimizing plant performance, predicting potential issues, minimizing human error, and enhancing decision-making through real-time insights and predictive maintenance capabilities. They are a crucial part of how modern plants stay ahead of the curve in terms of efficiency and safety.

The Hierarchical Architecture: A Watchful Eye at Every Level

Control and safety isn't a single switch or a lone computer; it's a meticulously designed hierarchy, with information flowing seamlessly from the smallest sensor to the main control room.

- Field Instruments: These are the unsung heroes, the eyes and ears of the plant. Thousands of sensors are strategically placed throughout the facility, collecting real-time data on everything from temperature, pressure, and flow rates to radiation levels. They are the first line of defense, detecting even the slightest deviation from normal operating parameters.

- Control Processors: Gathering data from the field instruments, these processors are the "brains" that analyze the flood of information. They make real-time decisions, often in milliseconds, and initiate adjustments to operations. If a parameter drifts, the processor might automatically adjust control rod positions or coolant flow, maintaining the reactor in its safe operating window.

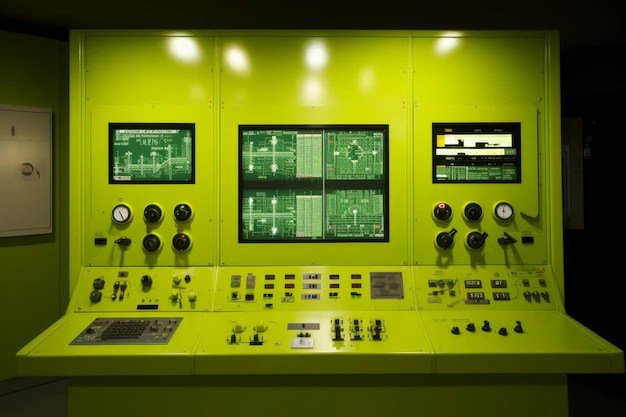

- Human-Machine Interfaces (HMIs): While automation handles much of the day-to-day, human operators are indispensable. HMIs are the sophisticated dashboards that provide visual data representation—think intuitive screens with graphs, schematics, and color-coded warnings. They facilitate operator interaction, allowing personnel to monitor vast amounts of information at a glance and respond rapidly to any abnormalities.

- Data Communication Networks: Connecting all these components is a robust, seamless network. These networks are built with extreme redundancy and fail-safe mechanisms, ensuring that critical data transfer between components is never interrupted. Data integrity and availability are paramount for quick and accurate decision-making.

Building a Fortress: Safety and Security Protocols

The design philosophy behind nuclear power plants is one of "defense-in-depth," meaning multiple, independent layers of protection. This philosophy is deeply embedded in the control and safety systems.

- Regulatory Oversight: Regulatory bodies, such as the U.S. Nuclear Regulatory Commission (NRC), mandate exceptionally strict guidelines. They require continuous monitoring, regular evaluation, and rigorous stress tests of all safety-critical systems. These regulations dictate everything from design principles to operational procedures, ensuring that plants meet the highest safety standards. Understanding these stringent frameworks can offer more insight into the world of nuclear power plant regulations.

- System Redundancy: Imagine having not just a spare tire, but three or four, each independently maintained and ready to deploy. That's the principle of redundancy. Critical systems are duplicated, often triplicated or quadruplicated, ensuring that if a primary system fails, a backup automatically takes over without any interruption to safety. This guarantees unwavering reliability.

- Fail-Safe Mechanisms: These are designed to automatically engage protective measures during anomalies or power loss. For example, control rods, which absorb neutrons and shut down the reactor, are typically designed to drop into the core by gravity if power is lost, ensuring an automatic shutdown. This intrinsic safety feature prioritizes shutdown over continued operation if a problem arises.

- Cybersecurity Measures: In an increasingly digital world, cyber threats are a serious concern. Nuclear plants implement robust cybersecurity measures, including multi-layered firewalls, regular security audits, and comprehensive training for personnel. These defenses protect against malicious attacks that could compromise control systems or data integrity, safeguarding critical infrastructure from digital intrusions. You can learn more about how crucial these protections are for other essential services by exploring cybersecurity for critical infrastructure.

- Real-time Monitoring & Automated Responses: Sophisticated algorithms constantly analyze data from thousands of sensors, detecting anomalies and subtle trends that could indicate a problem long before it becomes critical. If operational thresholds are exceeded, these systems are programmed to initiate automated responses—from adjusting reactor controls to activating emergency cooling systems—without human intervention, demonstrating the core strength of digital control systems and their benefits.

The Indispensable Element: Human Factors in Nuclear Safety

Even with the most advanced automation, humans remain a critical component of nuclear plant safety. Technology is only as good as the people who design, operate, and maintain it.

- Ergonomic HMI Design: The control room is where operators interface with complex systems. Ergonomic design, emphasizing clarity, intuitiveness, and clear color-coded warnings, is crucial. A well-designed HMI reduces cognitive load, minimizes the chance of human error, and improves operator situational awareness during high-stress situations. This thoughtful design helps operators quickly grasp complex data and react effectively.

- Comprehensive Training & Simulation: Operators undergo exhaustive training, often involving high-fidelity simulators that replicate every aspect of the control room. These simulations prepare them for routine operations, unexpected malfunctions, and severe emergencies, building familiarity and reducing hesitation when real-world challenges arise. This intensive preparation ensures operators can confidently manage any scenario.

- Culture of Communication & Teamwork: Beyond technical skills, a strong organizational culture is vital. Open communication, a questioning attitude, and a commitment to teamwork enhance safety. Operators are encouraged to speak up, share observations, and collaborate, reinforcing that safety is a shared responsibility. This collective vigilance forms another crucial layer of defense. The importance of human factors in nuclear safety cannot be overstated.

Navigating the Road Ahead: Challenges and Future Trends

The nuclear industry is dynamic, facing ongoing challenges while embracing innovative solutions.

- Aging Infrastructure: Many operational nuclear plants were built decades ago. Aging infrastructure can lead to malfunctions and inefficiencies, requiring significant investment and complex integration of new technologies to modernize components. This balancing act of maintaining older assets while upgrading to state-of-the-art systems is a continuous process.

- Evolving Regulatory Compliance: As technology advances and understanding of safety improves, regulatory requirements constantly evolve. Plants must continuously adapt to new standards, which often involves complex and costly upgrades.

- Future Trends: Digitalization, AI, and Machine Learning: The future of control and safety systems is increasingly digital. Artificial Intelligence (AI) and Machine Learning (ML) are poised to revolutionize operations through real-time data analytics, predictive maintenance (identifying potential failures before they occur), and optimized performance. These technologies promise even greater precision, efficiency, and safety, shaping the future of nuclear energy.

Real-World Resilience: Case Studies in Action

The effectiveness of these control and safety systems isn't just theoretical; it's proven in daily operation and emergency response.

- San Onofre Nuclear Generating Station (Routine Operation): This plant, though now decommissioned, exemplified precision in its operational phase. Its control systems precisely managed routine output increases and decreases, maintaining temperature and pressure within meticulously defined limits. This demonstrates the day-to-day capability of these systems to keep the plant stable and efficient under normal operating conditions.

- Fukushima Daiichi Nuclear Power Plant (2011): This tragic event is often cited as a failure, but it also highlighted the resilience of certain systems. Post-earthquake, control systems initiated automated safety protocols, successfully shutting down the reactors. It was the subsequent tsunami, which overwhelmed emergency cooling backup systems and external power, that led to the meltdowns. The initial response by the control systems and the operators' heroic efforts to manage cooling amidst the chaos reinforced the critical need for robust, multi-layered frameworks that can withstand even the most extreme unforeseen events. It underscored the importance of designing against station blackout scenarios.

- Virginia Power Nuclear Plant (Preventing Incident): In a less dramatic but equally crucial scenario, automated control systems at a Virginia Power plant identified a minor leak in a non-critical system. The system not only initiated auxiliary cooling to manage the issue but also immediately alerted operators to the precise location and nature of the problem, allowing them to intervene and avert a severe incident before it escalated. This exemplifies how real-time detection and automated preliminary responses can prevent minor issues from becoming major threats.

The Pillars of Protection: Key Safety Systems in Detail

Beyond general control, specific, independent safety systems are designed to mitigate the most serious accidents. These are the last lines of defense, often passive or automatically triggered.

- Reactivity Control System: This system is paramount for preventing the nuclear reaction from accelerating out of control.

- Control Rods: These are made of neutron-absorbing materials (like boron or cadmium). Inserted into the core, they literally "soak up" neutrons, slowing or stopping the fission chain reaction. They can be precisely manipulated for normal operation or rapidly "scrammed" (fully inserted) for an emergency shutdown.

- Automatic Control Systems: These sophisticated systems constantly monitor the reactor's power output and neutron levels, automatically adjusting the control rod positions to maintain the reaction rate within safe and desired parameters. If the reaction speeds up too much, the rods are inserted; if it slows, they're withdrawn slightly.

- Cooling System: Keeping the reactor cool is non-negotiable to prevent core meltdown.

- Primary/Secondary Cooling Circuits: The primary circuit directly cools the reactor core, carrying away the immense heat. The secondary circuit then uses this heat to generate steam for the turbines. These circuits are designed to transfer heat efficiently and safely.

- Circulation Pumps: Powerful pumps ensure a continuous and robust flow of coolant through the core. Loss of coolant flow is a serious concern, so these pumps are redundant and highly reliable.

- Backup Systems: This is where defense-in-depth truly shines. Nuclear plants incorporate multiple redundant and passive emergency cooling systems. These are often designed to function even without external power, relying on gravity or natural circulation to cool the reactor in the event of a station blackout or pump failure.

- Containment System: This is the most visible symbol of nuclear safety—a massive, high-resistance structure surrounding the reactor, designed to prevent the release of radioactive material to the environment under any circumstances.

- Double Containment: Many modern plants utilize double containment, featuring an internal concrete or steel structure encased by an external structure, providing an added layer of protection and an annulus for ventilation and monitoring.

- Filtered Vent Systems: In extreme pressure events within containment, these systems allow controlled release of steam and gases while retaining radioactive material through filters, thus preventing uncontrolled ruptures.

- Alarm & Detection System: Constant vigilance is key to early intervention.

- Radiation/Temperature Sensors: Thousands of sensors continuously monitor radiation levels throughout the plant and critical temperatures in various systems.

- Centralized Control Systems: These systems collect all sensor data, display it in the control room, and are programmed to provide immediate visual and audible alarms if any parameter deviates from its safe operating range, alerting operators to potential issues.

- Accident Control System: Should a severe incident occur, these systems are designed to mitigate its effects and bring the plant to a stable, safe state.

- Emergency Water Injection: In the event of a loss of coolant, high-pressure injection systems are ready to flood the reactor core with water, ensuring it remains covered and cooled.

- Gas Recirculation and Ventilation Systems: These systems help control the concentration of radioactive gases within the containment, preventing buildup and facilitating cleanup.

- Pressure Control Systems: Crucial for managing the immense pressures that can build up within containment during an accident, these systems ensure the structural integrity of the containment building.

The Human Element and Unwavering Oversight

Ultimately, the reliability of Control and Safety Systems in Nuclear Power Plants hinges not only on their design but also on the dedication of the people operating them and the rigorous oversight they receive. Thorough and regular training for personnel, including realistic accident drills and emergency preparedness exercises, is fundamental. It builds muscle memory, improves decision-making under pressure, and reinforces the importance of following established protocols.

Furthermore, nuclear plants operate under intense scrutiny. They are subject to strict government regulation, including frequent, unannounced inspections, comprehensive stress tests to evaluate their resilience to extreme events, and continuous safety reviews. This multi-layered approach—combining advanced technology, highly trained personnel, and stringent regulatory oversight—ensures that nuclear power remains a remarkably safe source of clean energy. You can delve deeper into how a nuclear power plant generates electricity and how nuclear power works to appreciate the complexity that these systems manage.

Staying Ahead: A Continuous Commitment to Safety

The world of nuclear power is one of constant evolution, driven by an unyielding commitment to safety. Control and safety systems aren't static; they are continuously upgraded, refined, and tested against new challenges, technologies, and understandings. From the earliest analog systems to today's advanced digital solutions, the journey has been one of increasing precision, reliability, and automated protection.

These systems are more than just technology; they are the physical manifestation of an industry-wide dedication to human safety and environmental protection. As you've seen, they are complex, redundant, and always on guard, working tirelessly in the background to ensure that the enormous power of the atom is harnessed safely and responsibly. The next time you consider nuclear power, remember the silent, ceaseless vigilance of these extraordinary control and safety systems—the true bedrock of secure energy production.